Whether you're planning to manufacture unique items or source existing products from wholesale suppliers, identifying the right partner is one of the most challenging steps in starting an ecommerce business. Many great product ideas remain concepts simply because founders don't know where to look.

But with the correct approach, you can identify the perfect manufacturing or sourcing partner for your venture. This guide will walk you through finding a manufacturer or supplier for your product ideas, offering advice for evaluating partners, deciding between domestic and overseas options, and asking essential questions about your future supply chain.

With these tips, you'll be on your way to sourcing the right products and laying a solid foundation for your business.

What is a Manufacturer?

A manufacturer is a business that converts raw materials into finished goods using tools, machinery, and human labor. Their primary purpose is to produce large quantities of products efficiently while maintaining consistent quality standards.

Most manufacturers specialize in specific product types. For example, you might work with one of the following:

- A glassware manufacturer for bottles and jars.

- A cardboard box manufacturer for packaging.

- A plastic goods manufacturer for containers.

Manufacturers are the entities that take your product specifications and turn them into tangible goods ready for consumers to buy, often customizing items to meet your specific needs.

What is a Supplier?

The term supplier is much broader, referring to any person, business, or entity that provides products, materials, or services to another business or consumer.

A supplier’s main goal is to ensure the availability and timely delivery of products or services to their clients.

Suppliers can include wholesalers, distributors, or traders who acquire products from manufacturers or other suppliers and manage the logistics of getting them to retailers. They essentially act as intermediaries between the manufacturer and the end-seller.

Here is the diagram which shows where suppliers and manufacturers fit in the supply chain:

Is a Manufacturer a Supplier?

No. While the terms are often used synonymously in practice, the main difference is that all manufacturers can be suppliers, but not all suppliers are manufacturers.

If a manufacturer sells its finished products directly to a business or consumer, it is acting as a supplier. However, a wholesaler who sources products from a manufacturer and sells them to you is purely a distributor, not a manufacturer.

Your business model dictates which type of partner you need:

- Manufacturers: Best if you have a unique product idea that needs to be produced from the ground up, or if you need custom parts.

- Wholesalers/Distributors: Ideal if you plan to resell existing, non-customized goods.

- Dropshipping Suppliers: For verified products where fulfillment and inventory are handled by a third party.

The Two Most Popular Manufacturer Types

If your goal is to create a branded product, you will likely work with one of two manufacturer types:

Private Label

This is a production setup where the manufacturer produces a product that you then sell exclusively under your own brand name. This model allows for high customization of ingredients, packaging, and design, though it typically requires higher Minimum Order Values (MOVs).

White Label

These are existing, ready-made products developed by the manufacturer and offered to various brands. They involve limited customization (usually just branding), making them a low-risk option with lower MOVs and ideal for market testing.

Domestic vs. Overseas Sourcing: Weighing Your Options

A fundamental decision in your product sourcing guide is determining the geographic location of your production. Choosing between domestic (UK-based) and overseas (international) manufacturing partners significantly impacts your costs, logistics, and supply chain risk.

Sourcing in the UK (Domestic)

Partnering with a UK manufacturer or supplier offers many operational advantages:

- Shorter Lead Times: Local production drastically cuts down on shipping delays, resulting in quicker inventory replenishment.

- Lower Freight Costs: Intra-UK shipping is generally cheaper and simpler than international freight.

- Easier Quality Control (QC): You can more easily visit facilities and personally oversee production runs to ensure quality.

- Simpler Compliance: Sticking to UK-specific regulations and labor laws is pretty straightforward, so it reduces regulatory complexity.

- Ethical Alignment: Supports your brand's ethical mission by ensuring compliance with established UK labor standards.

The main drawback is typically a higher cost per unit compared to international options, due to generally higher labor and material costs in the UK.

Sourcing Overseas (International)

Sourcing internationally from hubs like China, India, or Vietnam is mainly driven by cost advantages:

- Lower Unit Costs: Overseas production can offer the lowest cost per unit and works well when you’re ordering in very large volumes.

- Greater Capacity: You gain access to a huge network of specialised manufacturers who can handle almost any level of product complexity.

Still, international sourcing comes with its own complexity:

- Logistical Challenges: Shipping takes longer and costs more due to international freight and complex customs rules.

- Quality Control: Requires significant effort, often involving third-party inspectors, to maintain quality standards remotely.

- Regulatory Risk: Your business must remain informed about international trade laws and ethical standards to mitigate legal and reputational risk. You must ensure the manufacturer meets global ethical certifications like ISO.

The choice requires you to determine your ideal balance between product cost and supply chain reliability.

The 7-Step Guide to Finding and Vetting a Manufacturer or Supplier

Ready to turn your product ideas into reality? The process of product sourcing requires methodical research, clear communication, and diligent vetting.

Here is a seven-step guide to help you find a supplier for a product and secure the ideal manufacturing partner:

Step 1: Explore Your Sourcing Options (Where to Look)

Finding your initial leads requires you to use both local networks and global digital resources. Your choice of platform will determine the speed and scale of your search.

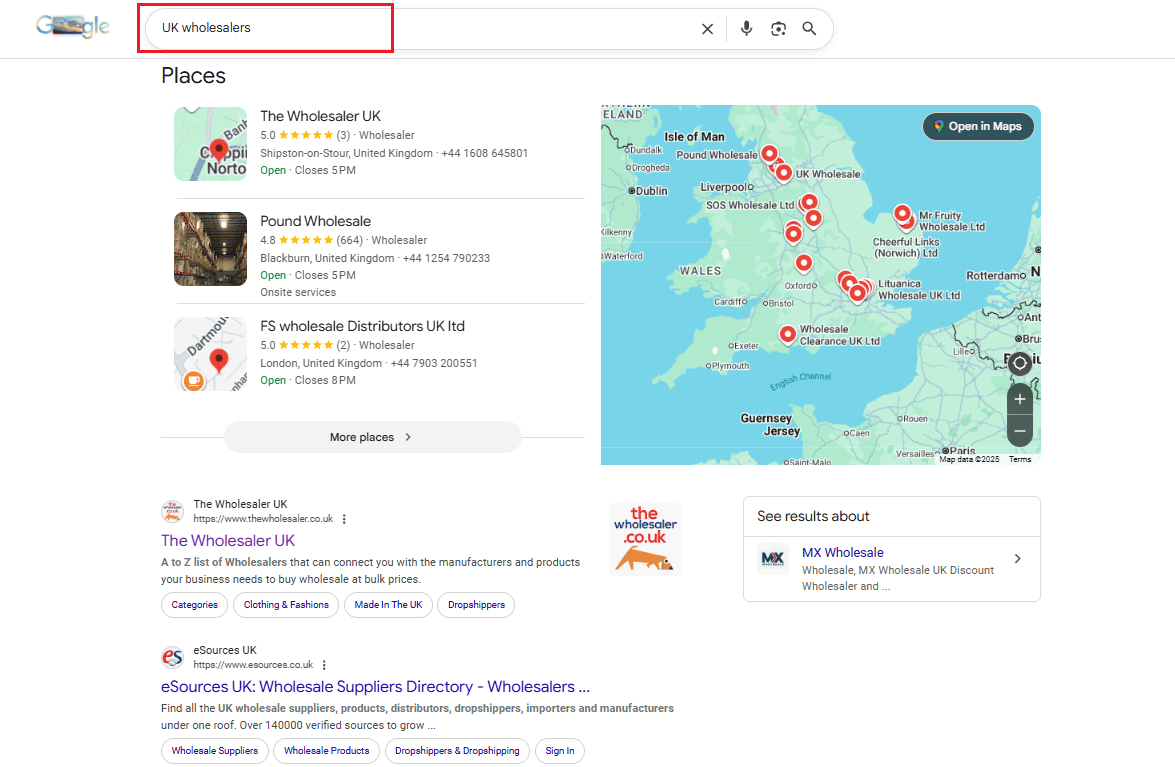

Online Marketplaces and Search Tools

Start with a simple Google search for local sourcing options using terms like "manufacturers near me," "UK wholesalers," or "supplier directory." You can try variations like “distributor” or “fabricator” to reach a wider range of results.

For sourcing wholesale inventory efficiently, platforms like Qogita stand out as a premier B2B marketplace. They can help streamline your sourcing process by connecting you with a wide range of verified suppliers. They also guarantee 100% authentic products, so it’s a win-win.

Now, if you want to source internationally, platforms like Alibaba (primarily for China) and Indiamart (India) are good resources. When using these, always look for trust indicators such as Gold Supplier status, Verified status (indicating a facility visit), and Trade Assurance.

Industry Networks and Referrals

One of the most reliable ways to find a manufacturer is through recommendations. Ask your professional network, reach out to successful entrepreneurs in your field, or join online ecommerce communities for trustworthy referrals and supplier reviews.

Attending trade shows and expos (both in the UK and internationally) also allows you to meet potential partners face-to-face, discuss capabilities, and assess the quality of their offerings firsthand.

But if you don’t have enough time or your product is complex, consider hiring a sourcing agent. This is an expert who can use their established network to find reliable, high-quality partners on your behalf.

Step 2: Research & Shortlist Potential Partners (The Vetting Process)

After identifying your initial leads, you must confirm that your potential partner has the stability, expertise, and reputation to anchor your supply chain. Always prioritize reliability over the cheapest quote.

For practical vetting, longevity is key. Focus on partners who have been actively operating in your product category for at least five years. This stability reduces your risk of future supply chain disruption.

Next, if you are seeking custom production, confirm you are dealing directly with the manufacturer, not an intermediary trading company. Cutting out the middleman eliminates unnecessary cost and reduces communication errors.

Finally, make sure the business is real and active. For UK companies, check Companies House to confirm they’re operating and in good standing. It also helps to see if they belong to relevant trade groups like Make UK, since membership usually shows they follow recognised industry standards.

Step 3: Gather Quotes & Request Proposals (RFPs)

Once your shortlist is finalized, it is time to clearly communicate your product requirements and assess the financial aspect of the partnership.

Requesting Quotes

You should reach out to at least three suitable partners to begin comparing costs, capabilities, and their initial responsiveness. Remember that the initial price quoted is often not the final figure.

Be aware of potential hidden manufacturing costs that can dramatically affect your budget, particularly when sourcing internationally. These hidden costs can include:

- International shipping, including complex customs duties and tariffs.

- Currency exchange rates.

- Tooling expenses for custom molds or specialized machines.

- Third-party quality control (QC) checks or inspection fees.

Communicating Effectively

To increase your chances of getting a timely and accurate reply, your first email must be precise. Avoid asking too many questions at first contact. Instead, focus on a high-level assessment of the potential fit.

When you ask for a quote, you must clearly define your product requirements. This includes materials, specific production techniques, and the estimated annual or initial quantities you require.

Knowing your target budget and ideal Minimum Order Values (MOVs) upfront allows the manufacturer to create a realistic proposal.

For larger or more complex projects, consider issuing a formal Request for Proposal (RFP). This document allows you to send one request to multiple suppliers, saving time and ensuring all parties are quoting based on the exact same specifications.

Step 4: Evaluate Communication, Quality, and Lead Times

Careful research and proper checks are absolutely necessary before you commit to any partnership.

Assess Communication

How quickly and clearly do they respond to your inquiries? Responsiveness and eagerness are strong early indicators of reliable service.

Pay attention to how effectively they handle complex technical questions. Miscommunication, particularly when sourcing overseas, can result in products that deviate from your specifications.

Quality Control (QC) and Transparency

It is very important that your supplier’s quality control practices are transparent. Find out about their inspection process, how they handle defective items, and how they ensure the materials they use meet your required standards.

You should ensure they have the technical ability and capacity to produce your specific product at scale and maintain consistent quality across all batches.

Lead Times and Capacity

Manufacturers must be able to deliver products fast enough to maintain your inventory and satisfy customer demand. Ask specifically about their average lead times (the time between placing the order and delivery).

Ensure they have the machinery, processes, and capacity to handle your projected order volume without sacrificing quality or punctuality.

Negotiate MOQs and Cost Per Unit

Although you already asked about Minimum Order Values (MOVs) in Step 3, you must negotiate the final figures now. Remember that MOVs are often negotiable. Generally, larger orders result in a lower cost per unit.

Exclusivity and Setup Fees

Ask if they can offer you exclusivity if you are investing significant capital into custom tooling or molds. It’s also important to check for any setup fees before you sign anything. These fees cover the work needed to prepare their equipment for your specific production run.

Step 5: Communicate Designs and Order Samples

Once a partner is shortlisted and you are satisfied with their initial quotes and communication, you must finalize the product design and verify the actual quality of their work. Never commit to a full production run without seeing a sample.

Communicating Your Designs

If you are developing a unique product, you must provide clear documentation of your idea. While some manufacturers offer costly product development services, alternatives exist. You can provide professional drawings created by an industrial designer or a Computer-Aided Design (CAD) expert.

Even detailed sketches and written instructions, along with reference photos, can effectively communicate your vision. Clarity here is paramount, as this documentation serves as the blueprint for production.

Ordering and Vetting Samples

The single most crucial piece of advice in the entire sourcing process is to always get product samples before committing to a full production run.

Why? Because the sample verifies the manufacturer’s capability, confirming the materials, fit, and finish meet your exact standards. This step prevents costly errors down the line.

Use the samples to evaluate the primary and secondary packaging options. Make sure these options meet any specific UK regulatory or transit requirements.

Once you are completely satisfied with a sample, date and sign it. Keep one or two copies for yourself. These signed control samples are your quality assurance benchmark.

If you later receive a bulk shipment with incorrect colors, dimensions, or materials, you can reference the control sample to prove the discrepancy to your supplier. It is absolutely vital for rework or refund claims.

Step 6: Negotiate Contracts and Terms

Once you are satisfied with the product samples and have confirmed the quality, you transition to the legal and financial backbone of the partnership.

The goal of this phase is not to win, but to establish a mutually beneficial, long-term relationship by clarifying expectations and balancing risk.

Payment Terms and Cash Flow

Inventory represents a high upfront cost for your business, so negotiating favorable payment terms is very important for managing cash flow.

Do suppliers negotiate? While new businesses may face requests for full payment upfront, most reputable partners are open to negotiation.

- The 50/50 Split: A common and favorable arrangement is to propose a 50% upfront payment to cover material and production costs, with the remaining 50% paid upon receipt of the shipment. This balances the risk for both parties and significantly helps your cash flow.

- Explore Escrow: If you are concerned about a supplier failing to fulfill their obligations, consider using an escrow service. This holds the funds in trust until the agreed-upon quality and delivery milestones are met.

Protecting Your Brand and IP

If your product involves some unique design elements or custom tooling, you must protect your investment through clear contract clauses.

- Exclusivity: If you are paying for custom molds or specialized equipment (tooling), negotiate a contract that grants you exclusivity over the final product. This legally prevents the supplier from using your investment to produce the exact same item for a competitor.

- Defect Policy: Clarity here protects your profit margins. Define clearly who is financially responsible for the cost of incorrect or defective items, including the shipping and duties fees required for returns or replacement runs.

A good negotiation marks the start of a healthy buyer-manufacturer relationship, focusing on a win-win situation rather than securing the lowest possible price

Step 7: Place a Pilot Run and Your First Order

After completing the meticulous process of vetting, sampling, quality control checks, and contract negotiation, you are ready for the final step: initiating production.

Start with a Pilot Run

Before committing to a high volume of inventory, conduct a smaller pilot run.

The pilot run is a final opportunity to test the manufacturer's capacity and consistency on a realistic scale without committing your entire budget to inventory.

It provides an opportunity to identify any potential production issues, logistical snags, or unexpected flaws that might only surface during the actual manufacturing process, so you can fix them before investing in thousands of units.

Evaluating Cost vs. Quality

As you place your final order, remember that choosing a manufacturing or supplier means constantly weighing cost against quality.

- Premium Materials: Better materials generally require higher upfront fees but lead to higher customer satisfaction, lower defect rates, and positive word of mouth. For instance, using durable materials in a product means customers are more likely to become repeat buyers.

- Target Audience Alignment: Your target market's needs must drive this decision. Budget-conscious customers may accept lower-cost materials, while clients seeking luxury or long-lasting items will demand and pay a premium for a superior finish and durability.

Moving Forward

Once the pilot is approved, the control samples are signed, and the contracts are finalized, you can place your first official bulk order.

This decision represents one of the highest initial costs of starting a business, so the patience and perseverance you applied throughout this product sourcing guide will prove invaluable in setting the stage for your business success.

Conclusion

Sourcing suppliers and manufacturers is perhaps the most important financial and operational decision when selling a product. It requires a lot of patience and research on your end.

However, by understanding the difference between manufacturers and suppliers, proactively vetting their stability, and negotiating terms, you lay a reliable foundation.

With the right partners, like Qogita, you can find 500+ vetted wholesalers and sell 100% authentic products with minimal effort.

How To Find a Supplier FAQs

What is the difference between a manufacturer and a supplier?

A manufacturer produces goods from raw materials (the maker). A supplier is a broader term for any entity that provides products or services, which includes manufacturers, wholesalers, and distributors (the provider).

Is it better to source domestically (UK) or overseas?

Sourcing domestically offers faster lead times, lower shipping costs, and easier quality control oversight. Overseas sourcing provides a lower cost per unit for high-volume orders, though it introduces greater logistical complexity and risk.

What are the most important things to check before partnering with a manufacturer?

You must verify the manufacturer's operational stability (at least 5 years in business), their commitment to transparent quality control, and their adherence to ethical labor practices and industry certifications such as ISO.

What is a Minimum Order Value (MOV)?

The MOV is the smallest number of units a manufacturer requires you to purchase in a single order. Although MOVs are high, they are almost always negotiable based on factors such as contract length or by offering a higher unit price.

Why are product samples so important?

Samples are crucial for quality assurance, verifying that the product materials, finish, and design meet your exact specifications before you commit to mass production. The approved sample serves as your legal control sample against future bulk shipments.

How can I protect my product design when working with a new manufacturer?

To protect your product design and proprietary processes, you must secure a robust contract that includes non-disclosure agreements (NDAs). Additionally, negotiate for exclusivity, especially if you are paying for custom tooling or molds.